Leaf Spring and Suspension U-Bolts

Order U-bolt kits online. Each U-bolt kit has two U-bolts with nuts and washers. We also make custom U-bolts (small and large orders).

To order online kits, click the type of U-bolt that you need. Find the U-bolt kit based on dimensions. Use our U-bolt Inquire Form to find out pricing of U-bolt sizes not listed in our standard kits. We also provide discount on large order U-bolt orders (bulk pricing) –> enter you information in the U-bolt form to get pricing.

U-bolts 9/16″ diameter and less are made from 1541 Grade 5 Material. Ubolts 5/8″ diameter and greater are made from Grade 8 material. U-bolts have a sufficient amount of rolled threads on each leg.We can also make most suspension u-bolts to your specifications and ship them out the same day. Please let us know the dimensions (as shown below), the type of bend, and the application. We can give you a price including shipping.

Custom or Quantity U-Bolt Price Request Form

LEAF SPRINGS FOR ALL MODEL TRUCKS/ HEAVY DUTY LEAF SPRINGS

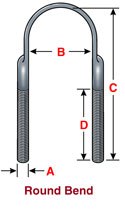

A U-bolt serves in four critical related roles:

• Primarily, the truck u-bolts provide the force required to clamp the leaf spring and related components firmly together. In addition to the leaf spring, these components include the top plate, axle seat, axle and bottom plate.

• The properly installed u-bolt eliminates any flexing of the leaf spring in the area between the u bolts. This is particularly critical since the hole for the centerbolt in each leaf acts as a stress concentration which would lead to rapid leaf breakage if spring flexing was not totally eliminated by the U bolt clamping force.

• By firmly clamping the spring to the axle seat the horizontal forces acting on the centerbolt are greatly reduced which in turn prevents shearing of the centerbolt.

• Proper clamping of the spring by the truck u-bolts provides the desired spring stiffness and contributes to maintaining the vehicle ride height and handling characteristics as originally specified for the vehicle.

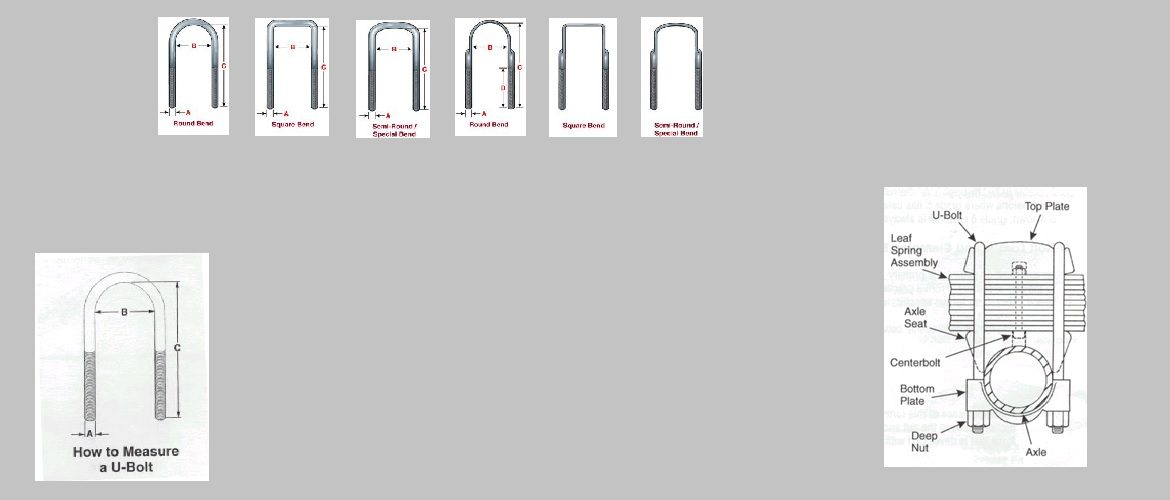

How to measure a Leaf Spring U-bolts

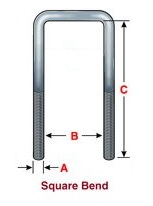

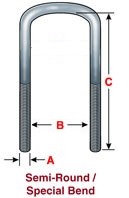

Regardless of the bend type, all Leaf Spring U-bolts are measured in the same manner as shown here. The U-bolt size is given as

Regardless of the bend type, all Leaf Spring U-bolts are measured in the same manner as shown here. The U-bolt size is given as

Diameter (A) x Distance Between Legs (B) x Leg Length (C).

Additionally the bend type must also be specified; either round, semi-round or square.

Do not reuse auto or truck Leaf Spring U bolts

• Used U-bolts will have rusted and damaged threads from the previous installation.

• A previously torqued U-bolt will suffer from distorted threads from the engagement of the deep nut. Deep nuts should be tightened once and re-torqued, never loosened and retightened.

• A used u bolt may have suffered from fatigue as well excessive stress since achieving accurate torque with commonly used impact wrenches is very difficult.

Rod/U-bolt Diameter Determination

Socket to Rod Size Chart

| Socket Size | Rod Diameter |

| 11/16″ | 7/16″ |

| 3/4″ | 1/2″ |

| 13/16″ or 7/8″ | 9/16″ |

| 15/16″ | 5/8″ |

| 1 1/16″ or 1 1/8″ | 3/4″ |

| 1 15/16″ | 7/8″ |

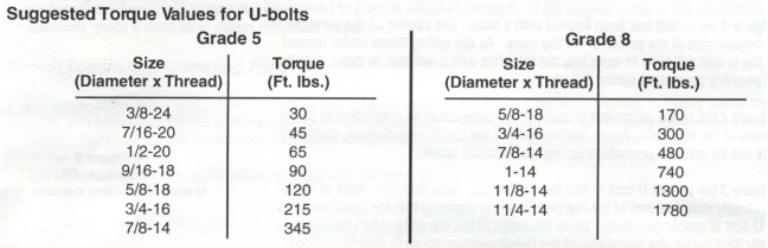

Torque Requirements

U-bolt Torque Pattern

U bolts must be tightened and torqued using a cross pattern sequence

-Tighten #1 then #4 to partial torque then partial torque #2 and #3

-Using the same sequence, fully torque U-bolt Nuts

U bolts that have been torqued to a set preload are recommended to be re-torqued after a short time to take-up the stretch in the set of the material.